If you already distribute your products using American cardboard boxes, automatic packaging is the ideal choice when production gets busy. For all other Clients, we will try to explain the pros and cons of this type of packaging solution.

How does american box automatic packaging work?

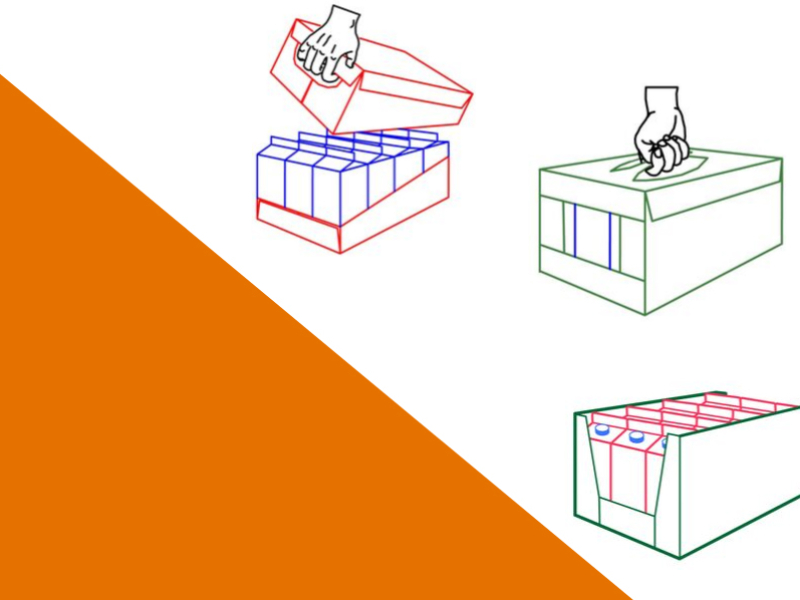

American box packaging requires the use of preformed cartons and consists of three phases:

- FOLDING – Die-cut cartons are collected from the warehouse with suction cup lifters and transferred to the folding area. In this phase, as well as in the following ones, mechanical movements require utmost care to avoid jamming and ensure continuous production.

- PICK-AND-PLACE PACKAGING – Products are collected and placed into the cartons.

- CLOSING – Packages are sealed with sprayed hot glue or adhesive tape. Most companies prefer hot glue as it simplifies opening the box.

As said, the automation of the pick-and-place and closing phases significantly improves the whole manual packaging process in terms of speed, precision and reliability.

Package distribution with american box

American boxes are generally used in the distribution of:

- Carton packages (e.g. Gable top)

- Glass bottles (e.g. wine bottles)

- Jars

- Cups

- Envelopes

The choice of this type of packaging is often related to industry practices. For instance, American box has always been the package of choice for bottles in the wine sector.

Only recently some wine-making companies have opted for other packaging systems, so as to differentiate their products and brands.

Automatic packaging for american cardboard boxes or wrap-around?

What are the main differences between American box and wrap-around packaging? Which solution is the winner?

Let’s see the pros and cons of American box packaging.

The pros

- Integrity: once opened, American boxes maintain their integrity even when partly emptied, allowing Clients to store the remaining products inside the cartons. Wrap-around boxes are no longer usable after being opened and must be completely emptied.

- Design: for shelving purposes, American boxes can be turned into trays once opened. The opening may also be customized with different cuts thanks to the upper tearing.

The cons

- Stability: in wrap-around packing, die-cut carton is folded around a whole product grouping, which limits the shifting of products inside the package. With American boxes, products remain quite loose and are at risk of breaking in case of sudden movements.

- Flexibility: wrap-around case packing offers a greater choice of formats and package types.

- Volume: with the same amount of products to package, American boxes occupy a larger space.

- Costs: American boxes are always thicker and require side seams to be glued. As a result, the final package is slightly more expensive than wrap-around case packing.

- Environment: adhesive tape tends to remains partly glued to cartons, which makes recycling more difficult.

American box packaging with Artema Pack

Artema Pack’s extensive experience in automatic packaging for American cardboard allows it to offer its Clients valuable advice in choosing the best packaging solution.

Automatic packaging systems are designed to offer more effective solutions to production needs:

- Quick format changeover: This is a key benefit for companies doing frequent changeovers in terms of box size, product and grouping. The changeover is performed without replacing any mechanical part.

- Reliability: Servomotor-guided movements are extremely precise and minimize the risk of downtime

- High-capacity carton warehouse: Artema Pack’s standard Pick-and-Place American box packaging machines allows storing 50-70 cartons, with the possibility of upgrading.

- Usability and maintenance: a number of new features, such as see-through windows on all sides, have been introduced to simplify the work of operators and servicing staff.

It goes without saying that all Artema Pack American box packaging solutions can be customized down to the smallest detail to optimize production and the final result.