A shrink wrapping machine (or shrink wrapper), that is, a wrapping machine which uses heat-shrink film, offers considerable savings compared to other end-of-line packaging systems, such as wrap-around or American box.

At the same time, it allows managing the entire production line with great efficiency.

In this article, we look at the main features of automatic shrink wrapping machines and the pros and cons of heat-shrink film packaging of food products.

How does a shrink wrapping machine work?

Shrink wrapping machines are packaging systems designed for carton containers. These include bricks, glass or PET bottles, pots and other containers.

They are mostly used in short-range distribution of food or beverage fresh products or no food products, the most notable example being multipacks of fruit juice bricks with straws.

The packaging process consists of several phases:

- Products enter the machine onto the infeed conveyor connected to the upstream machine

- Products are handled on multiple rows and grouped

- A base layer and/or vertical flap may be added

- Products are wrapped in heat-shrink film at controlled temperature

- Products are then transferred onto the outfeed conveyor

The multiple row handling system ensures uninterrupted production even at sustained speed (e.g. 7000 cartons per hour). By interacting with the upstream machine, the system efficiently distributes products on multiple rows with no downtime.

As with a wrap-around case packer, the systems allows setting and changing the type of grouping (e.g. from 6×2 packages to 3×4 or 3×3 packages).

How to choose the most suitable film package

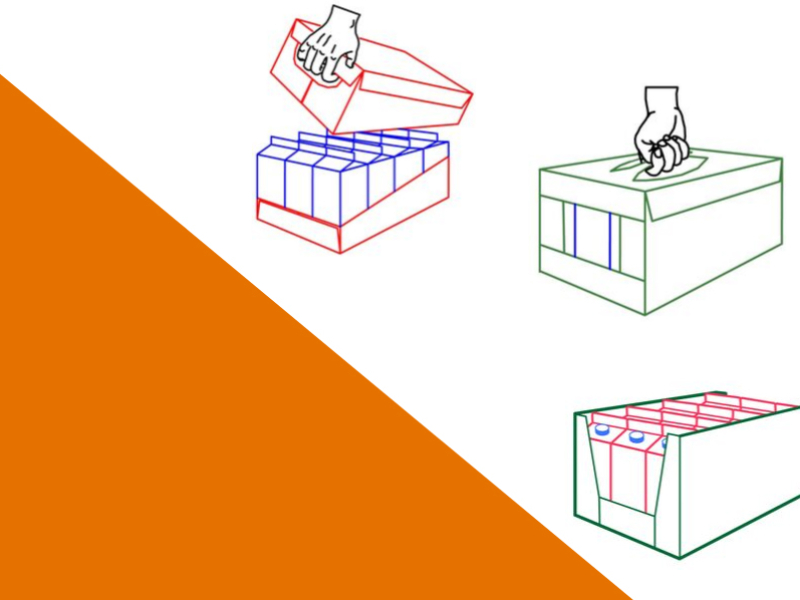

Depending on the product, one may choose among various packaging formats. The following packages are ranked by increasing robustness:

- Bundle with film only

- Bundle with film and a base layer

- Bundle with film and vertical flap

- Bundle with film, a base layer and vertical flap

The addition of a vertical protective layer increases the product carrying capacity and resistance to vertical compression during palletization. It therefore allows the addition of one or two extra layers on the pallets and to level the height of capped products.

This is important also from an aesthetic perspective, as packaged products look more orderly and are better protected against damage.

The vertical layer is not strictly necessary for hard liquid containers and for self-supporting bags of rice, pasta and other dry foods.

The film thickness depends on the fragility of the product packaging and the client’s needs.

While ensuring maximum robustness, a 100-micron thick film will require the highest energy consumption.

On the contrary, a film that is too thin may not be sufficient to protect the product. Packages are likely to break down during delivery and products risk melting or suffering damage before reaching their destination.

Heat-shrink film packaging: the pros and cons

The choice between film or carton wrapping (either wrap-around or American Box) is often related to the sector and country where the product is distributed, as well as to economic reasons.

However, for the same product, the choice of film wrapping compared to carton involves a number of pros and cons.

The Pros

- Convenience: heat-shrink film wrapping is less expensive than other packaging systems in terms of investment and secondary packaging costs.

- Compactness: heat-shrink film safely wraps the product like a second skin and protects it against external damage

- Resistance: the film bundle is resistant to mechanical stress due to transport and stocking

- Design: pre-printed heat-shrink film allows the product package to be decorated and made more recognizable

- Reel changeover: reels are replaced once a day on average, whereas carton requires regular refills. However, changing a reel takes about 10 minutes while wrap-around case packers require no downtime.

The cons

- Sustainability: heat-shrink film has a higher environmental impact than carton

- Lower carrying capacity: the most suitable packages are self-supporting packages, hard packages or those with limited height.

- Lower structural efficiency: compared to wrap-around carton, this system allows a smaller number of bundles to be stocked on pallets.

- Perception: products packaged with heat-shrink film are often associated to medium-low quality, especially in Europe

- Lower protection: the lack of hard elements may lead to product damage if the package is not handled and shipped with care

Artema Pack shrink wrapping machine

The Artema Pack shrink wrapping machine has been designed to offer an inexpensive, reliable and easy-to-maintain heat-shrink film wrapping system.

Over the years, our standard solutions have been integrated with bespoke features to meet our clients’ specific needs:

- Our high-efficiency ovens require -20% power compared to our competitors’ machines.

- The automatic handling system manages up to 1200 bundles per hour or 25 bundles per minute (i.e. In a 2×3 grouping, this corresponds to 7200 products per hour).

- Simple and quick format changeover

- Possibility of using 25 to 100 micron thick film

- Easy accessibility for ordinary use and maintenance

- Extreme usability and touch screen controls

All Artema Pack shrink wrapping machines offer a number of customizable solutions to guarantee the greatest return on investment and product efficiency.

These solutions are designed to boost the machine’s performance, to adapt it to a plant’s layout and to improve its functionality. For instance, it is possible to add a number of acrylic guard panels, a highly sought-after feature in the dairy sector.