How does a straw applicator work?

A straw and spoon applicator is an automatic machine. It works in a relatively simple way:

- the belt conveys the products from the filling machine at the start of the line

- the applicator sprays the glue

- the application head secures the straw in the desired position

- the product is conveyed to the case packer or the shrink wrapper at the end of the line.

Thanks to its photocell system, the automatic straw applicator works autonomously, detecting products and downtimes.

The straw applicator can apply up to 10,000 straws per hour; in the high speed version, the amount increases up to 18,000 straws per hour.

By adding another drum unit, straws/spoons can be applied on multi-pack formats on a double line, thus doubling machine performance.

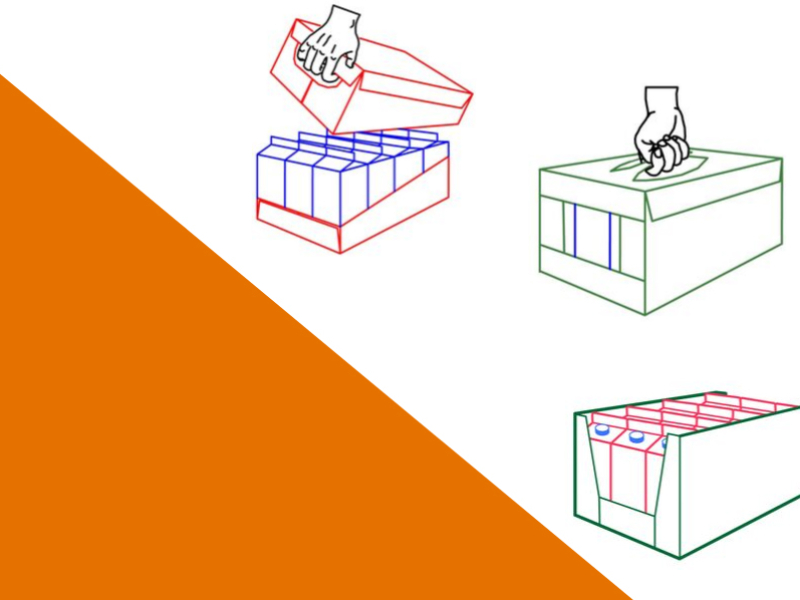

The machine’s flexibility enables the application of different types of straws – U-shaped, telescopic, straight – without having to replace mechanical parts. To modify the pace of the straws, a simple and quick replacement of the drum unit is needed instead.

Straw applicator: it’s all about versatility

The best straw applicator on the market is the one perfectly fitting your needs!

Versatility is therefore key when choosing a straw applicator. The automated system must handle spoons and straws coming in different dimensions and formats (straight, telescopic, U-shaped), providing the option to choose direction and application side. It must also accommodate packages differing in height and volume, as well as multi-pack formats.

In view of potential product integrations, a must-have feature is the bypass function, which enables alternate applications (one pack comes with a straw, one without).

Further criteria to consider when choosing straw applicator

Straw and spoon applicators are automatic machines requiring very low maintenance.

Proper planning is crucial to streamline standard processes, in particular for complex components, such as the glue unit, both for refilling and maintenance operations.

When handling packed liquids, which require aggressive cleaning to avoid the risk of contamination due to leaks, machines should be equipped with high-quality electronic components, to guarantee safety and reliability over time.

Ultimately, application precision is another important aspect. The applicator must guarantee a perfect positioning of the straw or spoon over time, to avoid waste and downtimes.

Artema Pack straw and spoon applications

The philosophy guiding Artema Pack in the planning and production of straw applicators is clear: the machine must adapt to the client’s processes and not the other way around.

Thanks to this approach, the company was involved in complex projects, coming up with innovative solutions, such as applying straws on non conventional materials or positioning them in unusual areas.

With an Artema Pack straw applicator, you can count on a high-performing and reliable machine, and also on yearlong expertise, which enables us to turn specific needs into solutions.