Food manufacturing and packaging companies make significant investments in their choice of packaging. However, they often underestimate the importance of the right package for safety and branding purposes.

Wrap-around case packing using trays and boxes is certainly one the most common end-of-line packaging systems.

But how does it work? And how to choose the most suitable wrap-around case packer?

We will try to answer these questions starting from the main features of this packaging solution.

How does wrap-around case packing work?

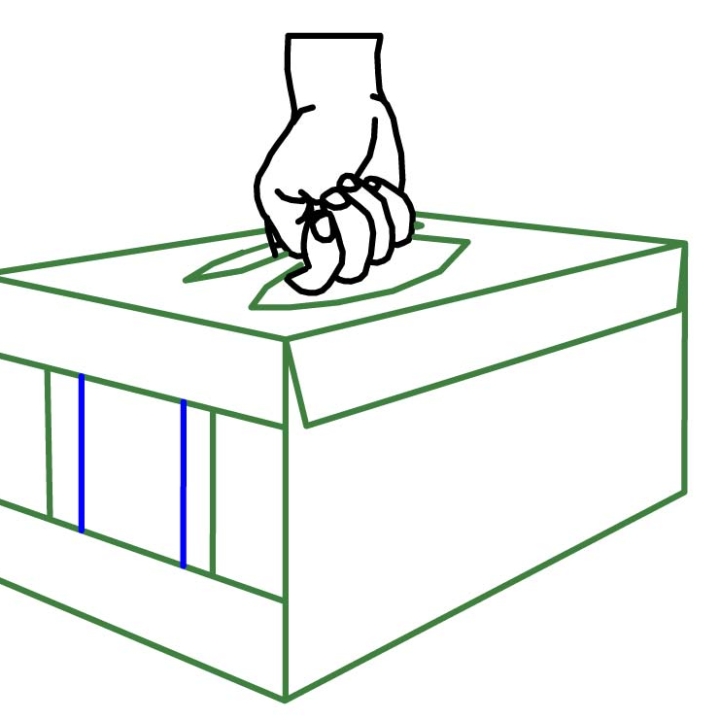

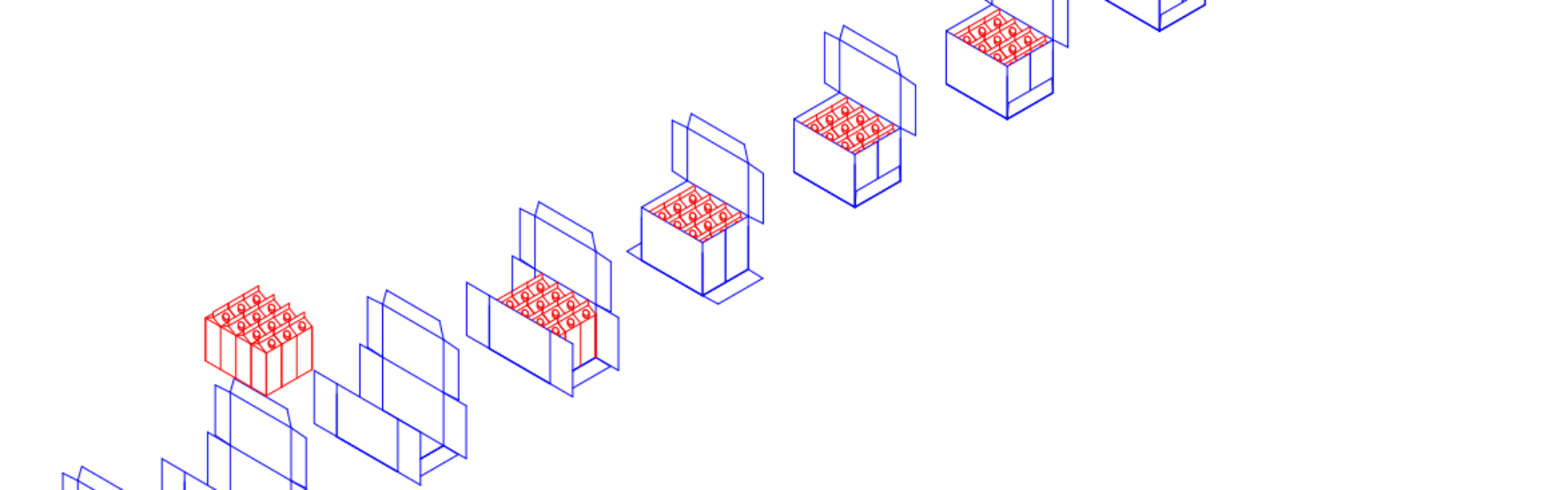

In wrap-around case packing, the carton blanks are wrapped and shaped around the packaging to form a compact and sturdy box, sealed with hot glue.

The folding and sealing of the cardboard around the product ensures greater compactness and integrity compared to the so-called American Box, a solution based on oversized packages, which may hinder stability.

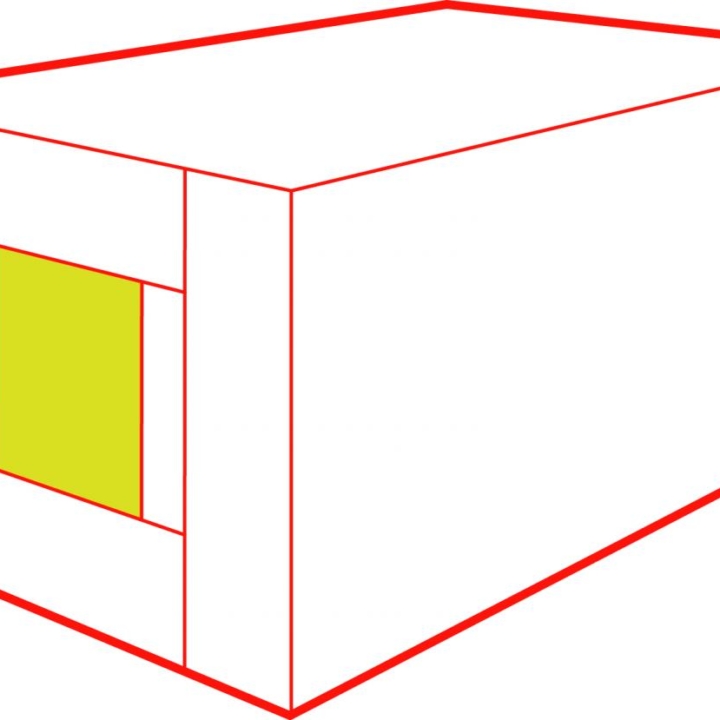

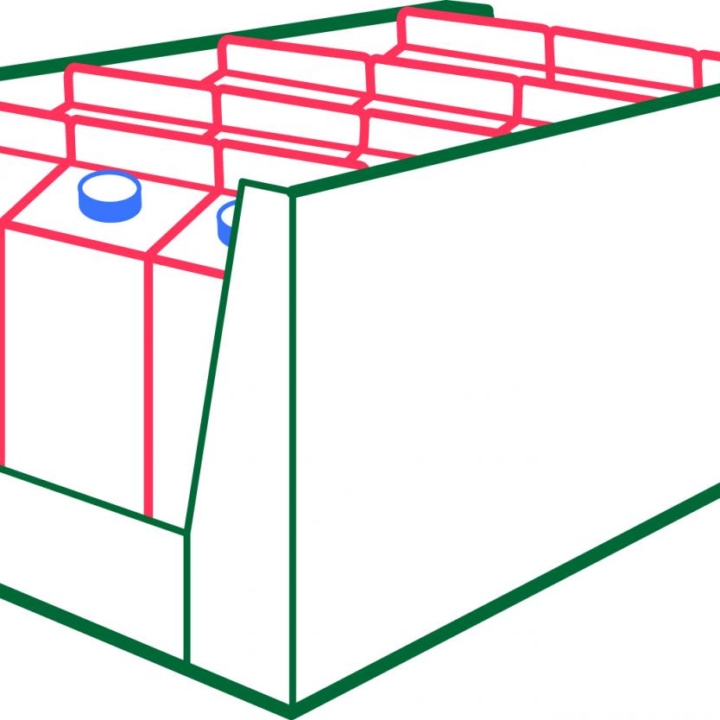

The package can be designed in various formats:

- Open tray with side walls of different heights

- Box with lid and built-in handle

- Tray with separate lid

- Tray with Flat Top

The packaging design can be further customized with the addition of carrying accessories, such as various types of built-in handles, shelf dispensers, and so on.

WHEN CAN A WRAP-AROUND CASE PACKER BE USED?

When thinking about product distribution, it is essential to find the right packaging solution.

This applies to logistics, seeking solutions to reduce overall dimensions and weights, without affecting the safety and protection of the products, but also affects a company’s ability to respond to the needs of large retailers, allowing the use of various types of packaging with different groupings (eg. 3×2, 4×3, 6×2, etc..).

In the food sector, the most common packaging solutions are:

- Tetra Pak® cartons of various sizes (for milk, fruit juices, vegetable drinks such as almond or soy milk)

- PET plastic bottles (for water, fruit juices and other beverages)

- Glass bottles (for wine, oil, and water)

- Bags of various sizes: double square bottom, square bottom with fin, cushion, etc..

Often the combination of secondary packaging and product is linked to industry practices. The majority of producers of fresh milk and fruit juices, so closely connected to the concept of naturalness, choose Gable Top for packaging and wrap-around cardboard for their end-of-line packaging.

On the contrary, the wine sector has always preferred the American Box. Only recently some producers have chosen to change their packing method as a differentiation strategy.

With the same purpose in mind, the choice of wrap-around case packing in a sector or a geographical area where the heat-shrink film is more widespread allows premium and more eco-sustainable products to be identified more immediately.

The fundamental factors to consider when choosing a case packing machine are:

- The possibility of multiple and fast format changes

- The ability to handle cartons of different thickness and quality

- Ease of maintenance

- Product quality, e.g. The use of stainless steel frames and elements

- Ergonomics

- Easy access to components for maintenance technicians

- Size

In addition to experience, the ability to offer a customised product is decisive when choosing a case packing machine manufacturer.

It is precisely the customisation that saves time and money, adapting the end-of-line packaging system to the context and to the production pace with a view to maximum efficiency.

THE BENEFITS OF WRAP-AROUND CASE PACKING

Is it better to choose a wrap-around boxing machine, a packaging machine for American cardboard or a shrink-wrapper for shrink film?

The answer depends, but for some factors it is the wrap-around case packing itself that wins the challenge:

FLEXIBILITY – Choosing a case packing machine capable of making size changes and groupings (e.g. from 3×2 to 4×3 or 6×2 packs) quickly allows companies to swiftly respond to the needs of large retailers and expand their customer base.

MORE SOLID PACKAGES – Wrap-around packing guarantees compact trays and boxes built “around” the product, and ensures greater integrity compared to the American Box.

SUSTAINABILITY – Companies that pay more attention to the environment can guarantee eco-sustainable packing across the board.

MARKETING – The freedom to customize the printing on the cardboard and to enrich the packages with dispensers or special shapes allows to differentiate the secondary packaging on the shelf, responding to the request for SRT (Shelf Ready Packaging).

COST SAVINGS – Although a greater investment is required than packaging with shrink film, wrap-around cardboard has a lower cost than American card.

Artema Pack wrap-around case packers

Artema Pack is made of a team of professionals with many years of experience in the field. This allows the company to build machines that are easy to use and maintain, offering solutions designed to meet concrete needs, and allows it to constantly improve them thanks to the work of its team and customer feedback.

Artema Pack wrap-around case packers are designed to meet the needs of large and small producers.

Large companies can count on customisable and extremely flexible case packers, with a very high reliability index and impeccable maintenance service.

The advantages for small producers come from the competitive price and small size of the case packing machine, as well as from the versatility and speed of format changeover and grouping that no other competitor can boast.

Producers of any size can count on expert and careful advice to choose the ideal wrap-around packing machine for their needs.