The machine can be set up to handle more than 15 formats and different grouping systems.

Wrap-around case packer

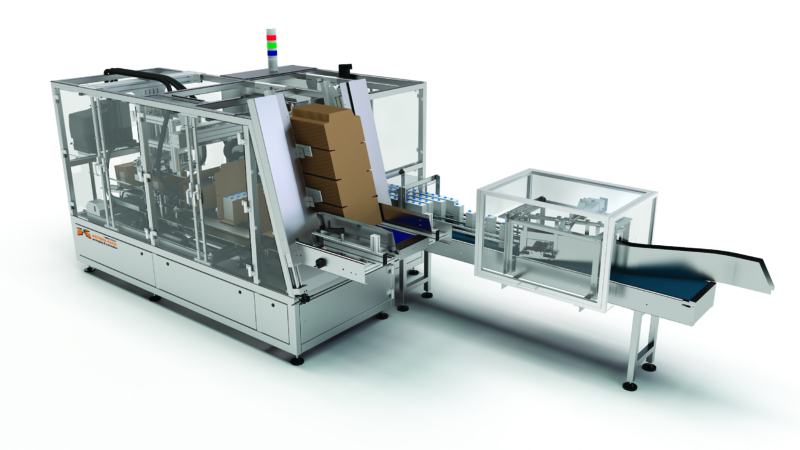

Efficiency, reliability and versatility make the wrap-around packer one of our flagship products. From the planning stage, every detail is designed to deliver solutions and high productivity.

Thanks to its compact dimensions and multiple layout configurations, our wrap-around machines can also be installed where floor space is limited.

A user-friendly operator panel and fast format changeovers optimize daily operations. Top brand components and a robust frame ensure reliability and durability even under intense operating conditions.

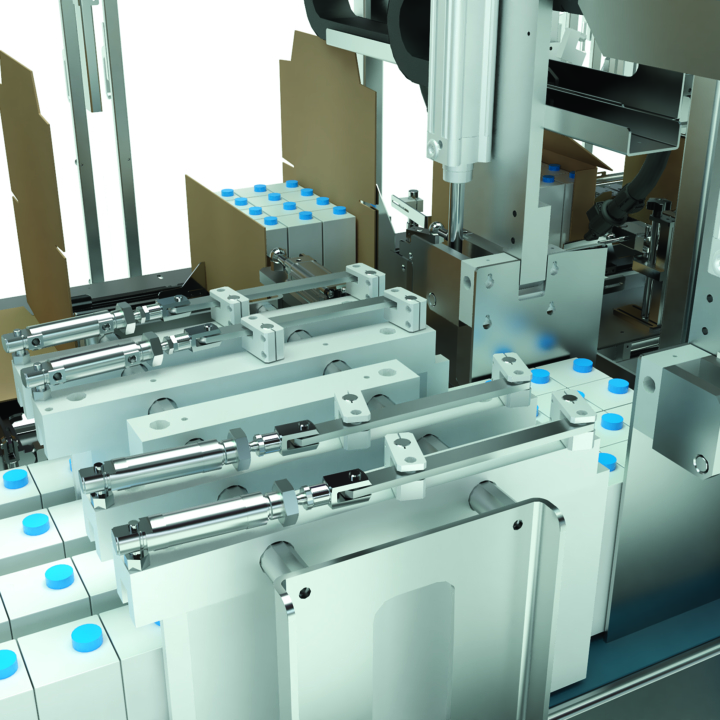

But the real added value of the machine is its versatility. The wrap-around packer can accommodate several types of containers and formats, such as brick packages, glass and plastic bottles, vials, jars, and a variety of multi-pack configurations.

The most common applications are:

- Open tray

- Fully closed box (with lid)

- Tuck top tray

- Tray with side panels varying in height

- Flat-top box

A single wrap-around machine can be configured to handle secondary packaging varying in shape, height and size, also using die-cut cartons with easy-open score lines and handles, for shelf display and greater convenience.

In terms of sustainability, a wrap-around system is an excellent solution due to the very nature of the packaging method. The package is wrapped in cardboard, which protects integrity with minimal material consumption. The cardboard itself can be recycled to further reduce its environmental impact.

Artema Pack can integrate wrap-around case packers into highly efficient automated systems, to accompany packages through the journey from the packaging machine to the palletiser.