The multi-format wrap-around case packer is the solution for forward looking clients!

Often, when choosing a case packer, only present needs are considered, without thinking about the essence of business: growth.

Let’s assume that we are acquiring a new client, who requires a different primary pack (in volume, section or dimensions), in a different packaging format or in a different box type.

What to do then? Buying another packer is unthinkable. An upgrade is uneconomic.

The solution? Thinking long-term, setting up the machine for different packaging types right away.

WHO NEEDS A MULTI-FORMAT CASE PACKER?

We feel the correct answer is everyone, whatever current and future requirements may be:

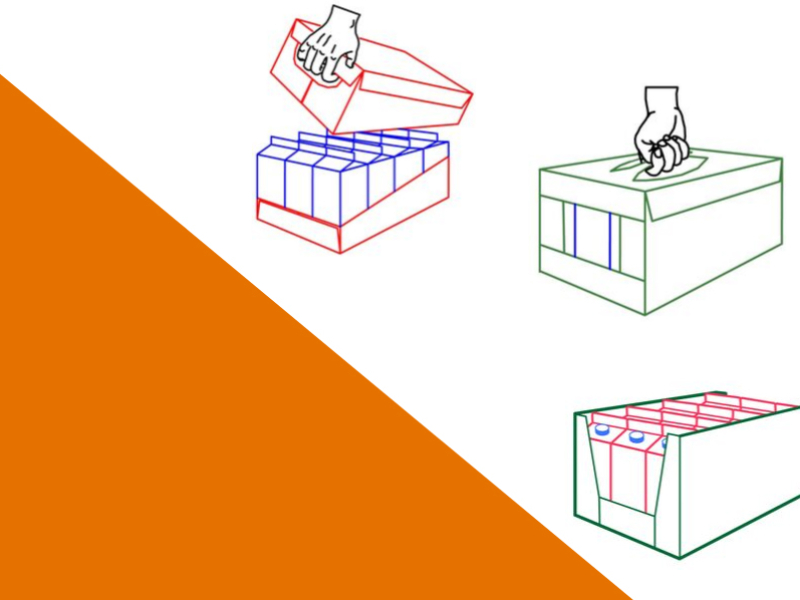

● SAME PRIMARY PACK – BOXES IN DIFFERENT DIMENSIONS

In this case, the machine needs to be set up to change the box groupings and dimensions, with a quick format changeover, without the need to replace mechanical parts.

● DIFFERENT PRIMARY PACKS – SAME BOX

For those wishing to handle several formats at infeed – same category packaging (such as Gable Top cartons) in different dimensions, or different packaging types, like plastic bottles and Gable Top cartons – the case packer needs to be set up with a multi-line management system with adjustable guides and simplified grouping changeover set-ups.

● DIFFERENT PRIMARY PACKS – DIFFERENT BOXES

Once again, design makes the difference. The goal? Reducing format changeover times, eliminating the replacement of assembly groups!

NO REPLACEMENT OF MECHANICAL PARTS NEEDED

How do you develop a multi-format wrap-around packer that can ensure a format changeover taking from 2 to maximum 15 minutes?

By efficiently optimising, simplifying, and designing guide-rails and set-ups!

Artema Pack’s wrap-around case packers are designed to enable format changeovers without having to replace assembly groups, thanks to a simplified manual adjustment system:

- Carton magazine with rev counter hand cranks to position boxes correctly and to reset their dimensions: height-width, box length-flap closure.

- Rotary settings to adjust feed chains.

- Template system to adjust flights depending on box size.

Does it sound complicated? It isn’t at all. Each case packer comes with an extremely simplified set-up manual, which allows for easy and quick adjustments.

ADVANTAGES OF FORMAT CHANGEOVER WITH MANUAL SETTINGS

The removal and installation of assembly groups is a time-consuming operation which, though performed occasionally, requires time, energies and trained personnel.

On the contrary, a case packer with manual settings has several advantages:

- The set-up can be carried out by a single operator, including non-experts.

- There is no need to handle equipment for assembly groups.

- Required warehouse space is reduced to zero, since no further parts are needed.

How many formats can such a machine handle? More than you can imagine!

14-FORMAT WRAP-AROUND CASE PACKER

In early 2019, we designed a wrap-around case packer that can handle 14 different formats.

At infeed, the machine can accommodate 2 brick carton types – 500 ml, in variable heights, and 1 litre – as well as a square format.

At outfeed, available formats are tray, box with lid and flat top.

The machine can handle 6 (2×3), 8 (2×4) and 12 (2×6) packs.

The result? A multi-format case packer that can perform super-fast format changeovers, without the replacement of mechanical parts.

This is what we call thinking long-term.